Manufacturers of advanced PCB (printed circuit boards) assembly know that simultaneously producing cost competitive products and meeting the quality expectations of customers are vital to their success.

Electronics

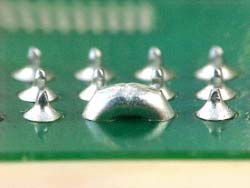

Identifying the PCB shorts, PCB voids, opens, misalignments and solder integrity of area-array chip packages is crucial. The SMT (surface mount technology) circuit assembly consists of three major processes:

- Solder paste inspection

- Component placement

- Post re-flow inspection

The use of a microscope is becoming essential as the components of the boards are becoming smaller so that the PCB can hold more components.

Accurate PCB inspection

In the intricate task of PCB manufacturing, reliable inspection and measurement of different connections, vias and clearances is paramount during and after production. Microscopes are utilized in PCB inspections to enable users to improve quality and increase output.

The Mantis inspection microscope is used in FAI (First Article Inspection), which is a requirement to ensure that the first product produced is 100% correct. In our industry, we need to ensure that the first off from the SMT assembly line is perfect before running the rest of the batch.

Mantis stereo microscope, ideal for electronics PCB inspection and rework

Mantis is a stereo microscope ideal for electronics PCB inspection and rework. The patented optical viewing head of Mantis provides unrivalled 3D images, plus significant ergonomic advantages, where fatigue and eye strain associated with working under magnification are eliminated.

6,950 total views, 3 views today